FX / MBX PERMANENT MAGNETIC LIFTER

Product Introduction

FX / MBX

PERMANENT MAGNETIC LIFTER (ON/OFF TYPE)

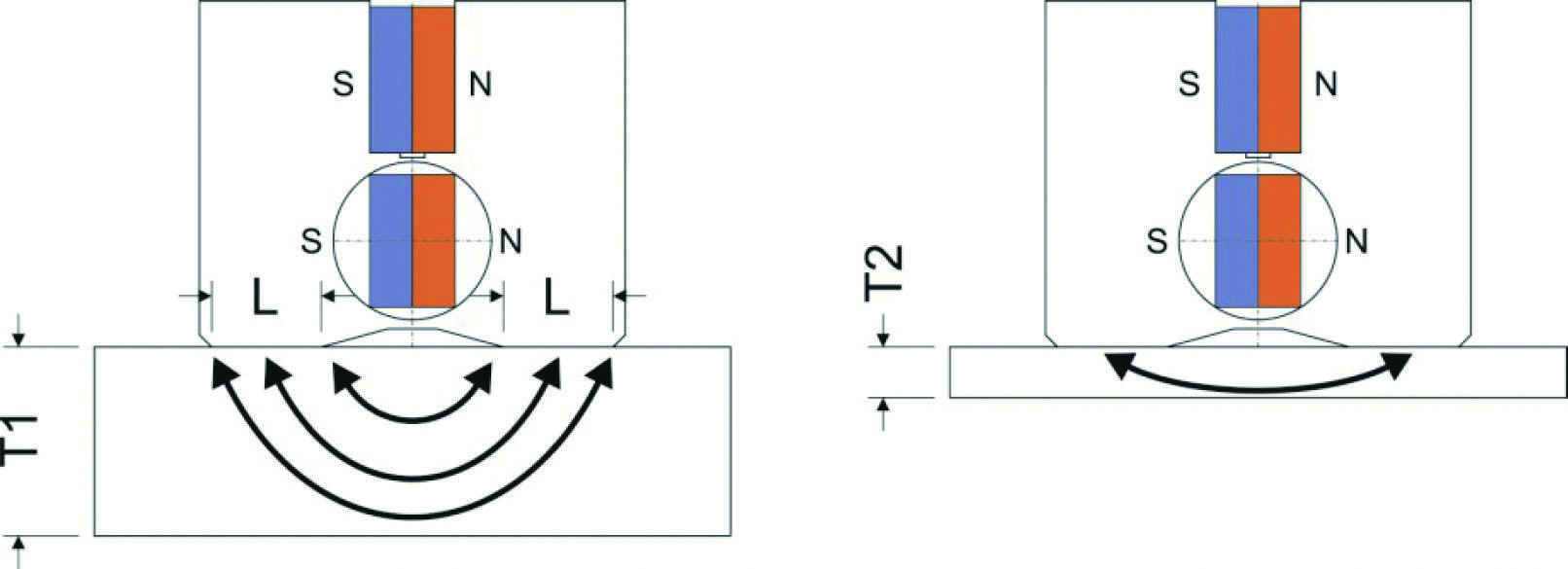

Application: Suitable for holding and moving flat and round materials.

Features:

- Small size, strong magnetic force, and easy to operate.

- Massive shift shaft with half-shell NdFeB magnets, ON/OFF switching only 90°.

- Recoilless hand operation.

- Workpiece temperature should be under 80℃.

- Safety Factor 3.5 .

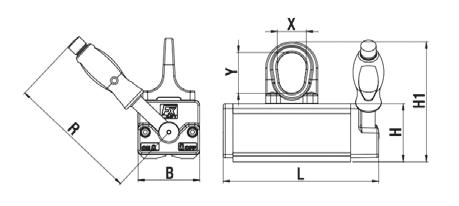

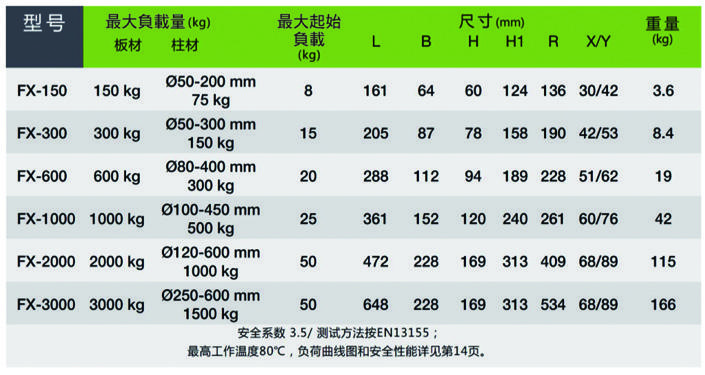

FX

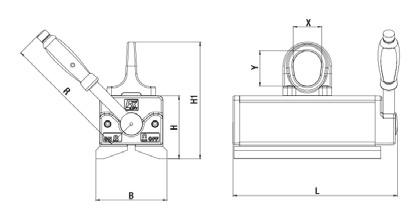

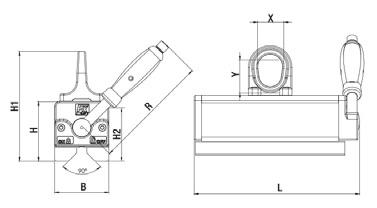

FX-R

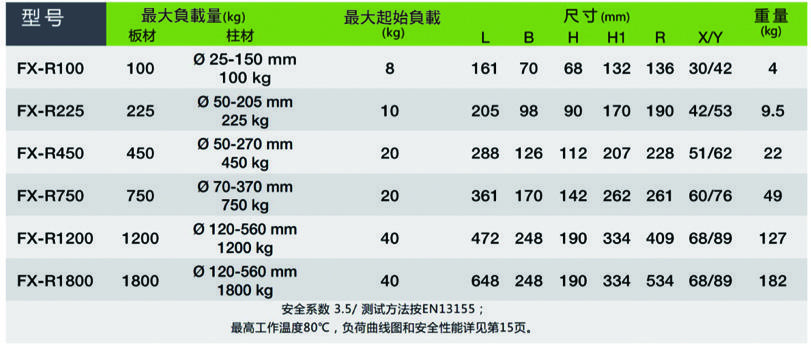

FX-P

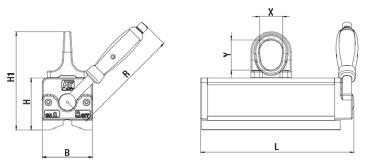

FX-V

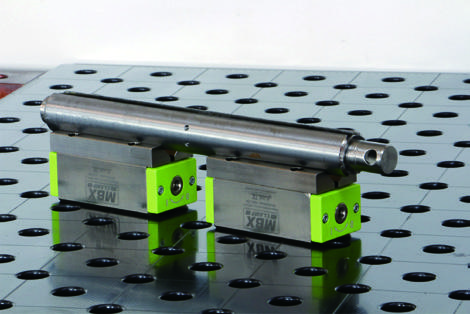

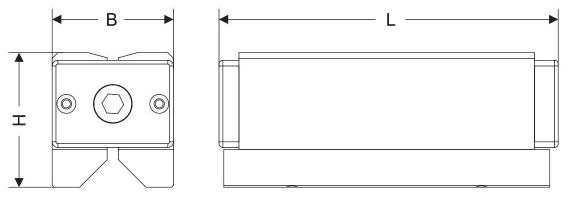

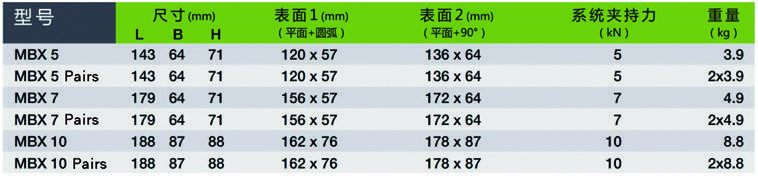

MBX

The workpiece can be fixed regardless of the column shape, sheet or other profiles, and can be connected in series to hold longer or larger workpieces.

5 factors for choosing the right lifting magnet model

1. The contact surface

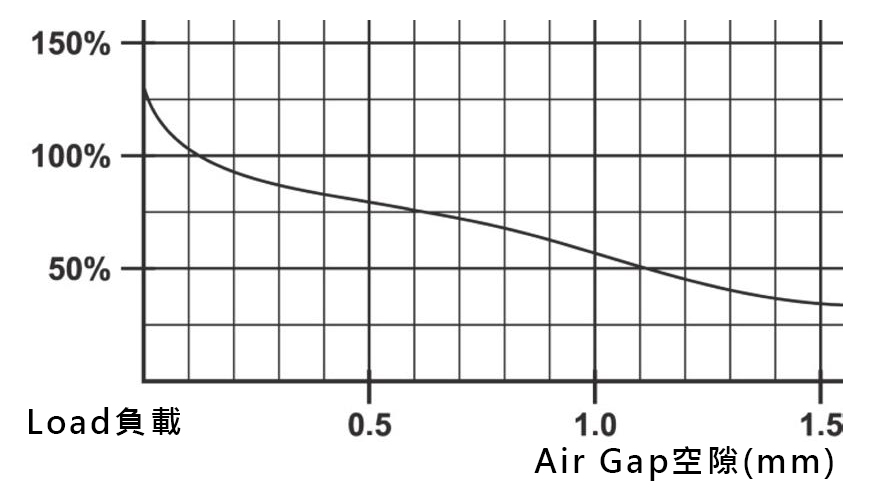

If air gap (ex: Rust, paint, dirt, paper or rough machined surface) exists between the lifting magnet and workpieces, the magnetic flux is made more difficult and thus reduces the lifting capacity.

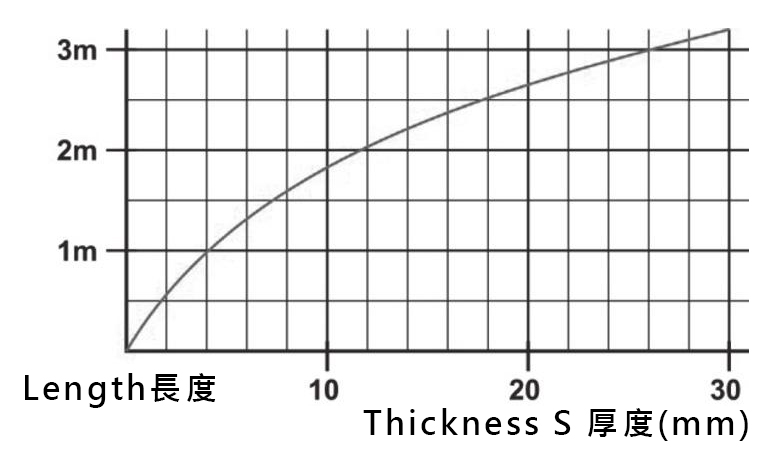

2. Material Thickness

Minimum material thickness is required, If workpiece doesn’t reach this minimum thickness, the lifting force is smller. For larger lifting benefits greater material thicknesses are required.

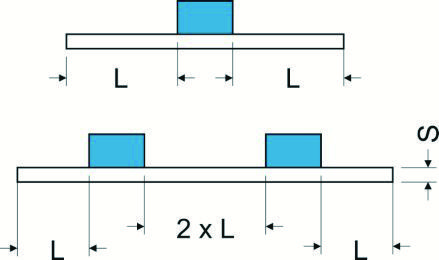

3. Workpiece dimensions / intrinsic stability

If the length or width of workpieces is larger, the workpiece sags and is formed between the lifting.

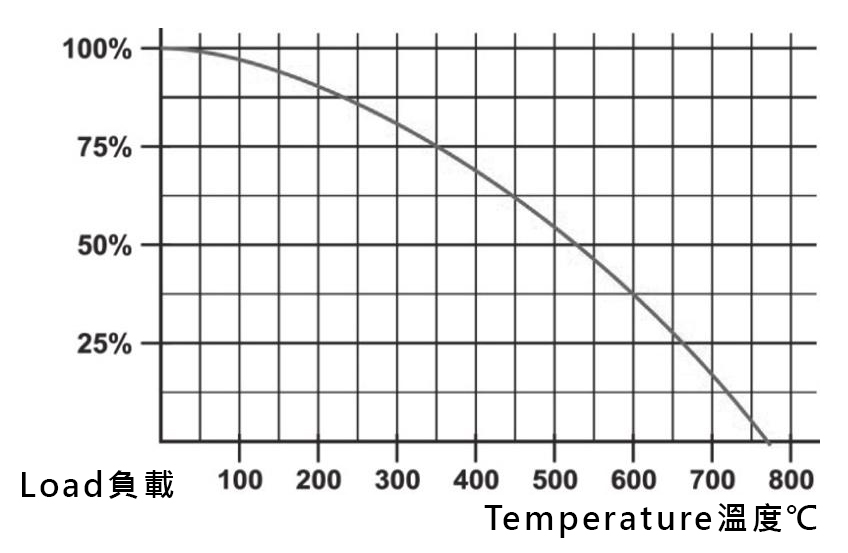

4. Temperature of Workpieces

Temperature of Workpieces affects lifting capacity. This data applies to Max. 80℃.

5. Workpieces material

| Material | Lifting Power(%) |

|---|---|

| Carbon Steel (0.1~0.3%C) ST37/52 | 100 |

| Carbon Steel ( 0.4~0.5%C ) | 90 |

| Alloy Steel 2312/2379 | 80 ~ 90 |

| Cast iron GGG | 70 ~ 80 |

| Cast iron GG | 45 ~ 60 |

| Stainless Steel ( HRC 55~60 ) | 40 ~ 50 |

| Brass, Aluminum, Copper | 0 |